9-23-2024: The HVAC&R Weekly Edition: Issue #16**

We all know about Superman's super powers, Wolverine, aside from those razor sharp knives coming out of his knuckles, was just general badass. Working with Advanced Offsets could be your super power!

** SURPRISE! It’s 5-26-25: I typically make an effort to properly finish those things that I start. This one took a little longer than I anticipated. I apologize for not getting this Issue #16 out to the team sooner. Apprenticeship classes started up and I had to direct most of my time an attention to getting a new curriculum together.

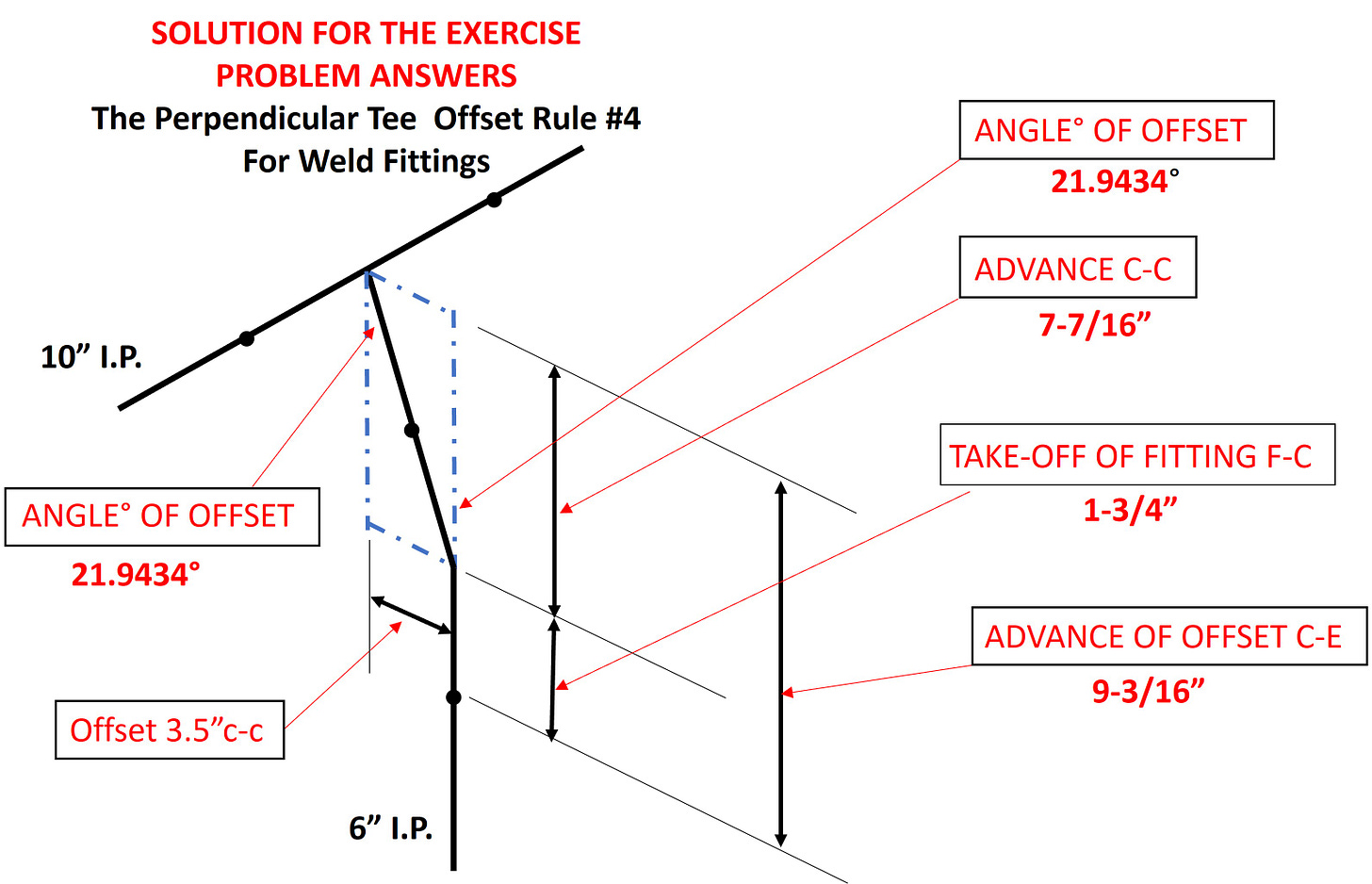

In the Issue #15 I left you with a problem to solve. It was utilizing one of the Perpendicular Tee Offset problems. This offset had 10” I.P. header, with a 6” I.P. branch. The branch had an offset of 3.5”c-c. Here is an illustration of the problem I presented.

THE PERPENDICULAR TEE OFFSET

THE PERPENDICULAR TEE OFFSETTING 3.5”

If we go back to last weeks exercise, we see that we need to find the Reference Angle and the Angle Factor for this offset configuration. We need to look up the specifications of the Tee we will be using this might help.

Calculating The Reference Angle (Example 6” Branch on a 10” Header with a 3.5” offset )

Reference Angle = (Rad. 90°÷ Tee f-c)tan⁻¹

Select a 10 x 10 x 6 weld Tee with a 6” I.P Branch connection for our example.

12 x 12 x 4 Weld Tee face to center = 7.62” (see weld bend catalog pg. 53)

6” Weld Bend 90° → 6” x 1.5 = 9” Radius

Reference Angle = (9”÷ 7.62”)tan⁻¹ → 49.7465°

The less than dimension will be any offset less than 9” and will have an angle greater than 0° but less than 49.7465°

The greater than dimension will be any offset greater than 6” but less than 16.62” and will have an angle greater than 49.7465°but less than a 90°.

So we were able established out Reference Angle, and we also determined that we need to use the Perpendicular Offset Tee Formula #4 (Less than). Now we need to calculate the Angle Factor to solve the problem. Here is the procedure to do that.

Calculating The Angle Factor (Example)

Using the calculated reference angle (see above)

Angle° sin = Ans* 1/x = Cosecant of the Angle Factor

49.7465°sin = .76319 → 1/x = 1.3102 Cosecant of the Angle Factor for our problem.

We now have a clear picture of our next series of calculations using the Less Than Perpendicular Tee Offset.

Perpendicular Tee Offset Formula #4 (Less Than)

Offset Angle less than = (Rad. 90° - Offset)÷(Rad. 90° x Angle factor) = *Ans.

Ans* sin⁻¹ = Angle° → Reference Angle° - Angle° = Angle of Offset

Perpendicular Tee Offset Formula #4 (Less Than)

Offset Angle less than = (9 - 3.5)÷(9 x 1.3102) = .466425

.466425 sin⁻¹ =27.802° → 49.7465° - 27.802° = 21.9434° Angle of Offset

With the Angle of the Offset we can now find the fitting take-off and advance of the offset.

Take-off of fitting = (21.9439°÷ 2)tan x 9” = 1.744”

Take-off of the fitting= 1-3/4” c-f

Advance of offset = (3 ÷ 21.9434° tan) = 7-7/16” + 1-3/4” = 9-3/16”

Advance of the Offset Center to Face = 9-3/16” c-f

Use data to layout mitered fitting.

21.9434°Perpendicular Tee Offset With Dimensions.

Let’s look at an alternative way to miter that 21.9434° fitting. Instead of using a 90° weld bend fitting we can use a 45° weld bend fitting for this application because the angle of the offset is less that 45°. We still calculate the ISA and OSA arc lengths as before. We would also figure the Rise dimension as if you were using a 90°weld bend fitting, applying the Sine of the desired angle and the radius of the 90°to find the rise. We will then flip the 45° weld bend over but instead of using the Cosine of the desired angle we will subtract the angle of the offset from the 45°degree fitting and then use the Sine function of that difference to find the Rise II dimension. See the procedure below.

MITERING OUR FITTING FROM A 45°WELD BEND FITTING

Find the center line Radius (takeoff) for a 6” 45° weld bend 6 x 1.5 = 9”f₂c

Find the OSA→ (Outside Arc-Length) for a 21.9434°mitered fitting from a 45° weld bend fitting. O.S.A. = (9 + 3.3125) x .01745 x 21.9434° = 4-11/16” O.S.A.

Find the ISA→ (Inside Arc-Length) for a 57.826°mitered fitting from a 45°weld bend fitting = I.S.A. = (9 - 3.3125) x .01745 x 21.9434° = 2-3/16” I.S.A.

Find the Rise dimension for the Quadrant Mark for a 21.9439°→ 21.9434°sin x 9 = 3-⅜” Rise dimension.

**Find the Rise II dimension for the Quadrant Mark for a (45 - 21.9434°) = 23.0566°→ 23.0655°Sin x 9 = 3-1/2” Rise II dimension

See the process of the layout in this series of slides below.

START BY LAYING OUT THE ISA AND OSA ARC LENGTHS

START BY LAYING OUT THE ISA AND OSA ARC LENGTHS FOR THE ANGLE OF THE OFFSET.

Once those are laid out we can lay out the Rise based on the angle of the offset. See below.

NEXT LAYOUT THE RISE DIMENSION USING THE SINE OF THE ANGLE OF THE OFFSET.

NEXT LAYOUT THE RISE DIMENSION USING THE SINE OF THE ANGLE OF THE OFFSET. (Quadrant Mark I)

As you can see the first two steps are the same as if we were using a 90° weld bend fitting. Lets see how we find the the final Quadrant Mark (Rise II dimension)

FINISH BY FINDING THE RISE II DIMENSION USING A 45° FITTING AS OUR BASE

FLIP THE 45° FITTING AND LAYOUT THE RISE II DIMENSION USING THE SINE OF (45° - THE ANGEL° OF THE OFFSET). (Quadrant Mark II)

As you can see we don’t need to deal with an angry foreman who gets bent out of shape when we cut up perfectly good 90° weld bend fitting to achieve a desired angle that is less than 45°. Especially when we have a 45° fitting laying around that we can extract that from instead.

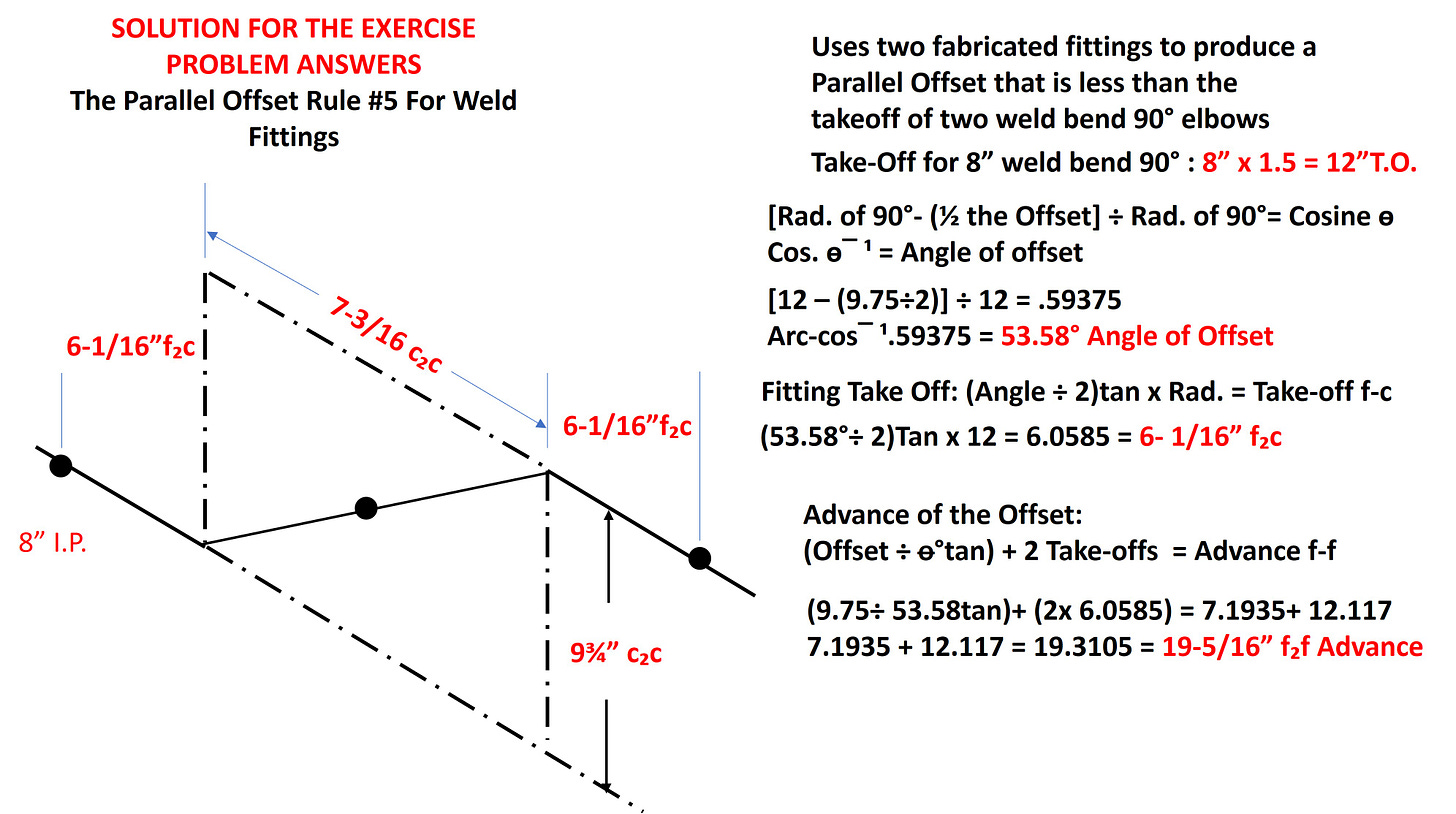

THE LAST OF THE FIVE OFFSETS THE PARALLEL OFFSET.

The fifth and final offset is a parallel offset that s less than the takeoff of two back to back 90° weld bend elbows. The formula is surprisingly simple and I’m amazed it isn’t used more often.

Using the techniques for laying out these fittings should make this an easy fit up. I promised you five unique offsets that could get a good fitter out of a pinch or reduce the weld inch count. Beside when used appropriately they make you look like a badass! (In a good way.)

That covers the material that I wanted to finish presenting back on 9-23-2024. I am currently working on another HVAC Series dealing with pumps, pump curves, and the formulas we commonly use in the HVAC industry to analyze Chiller performance.

Until then hang in there, be patient, and most of all be safe on this Memorial Day Weekend

Good to have you back!