6-23-2025 The HVAC&R Weekly Edition: Issue #20

"The best way to navigate a tight curve is to lean in, and accelerate through it. That little Yellow Speed Sign ahead, it’s just a recommendation Honey." One of many sweet assurances to my wife.

Just like learning to deal with the centrifugal forces working against a motorcycle in a tight turn, we can learn to navigate the data in a pump curve as well.

In our last Session we used W.H.P. and B.H.P. calculations to analyze the horsepower requirements in several flow scenarios brought about by a well intentioned fictitious character. We found that the addition of glycol changed the Specific Heat and Thermal Conductivity of the water/glycol solution which affected the Chillers capacity, but it affected the pumps performance as well. In this self imposed concoction of woe, we were presented with three possible schemes. Today we use a series of pump curves to illustrate those effects.

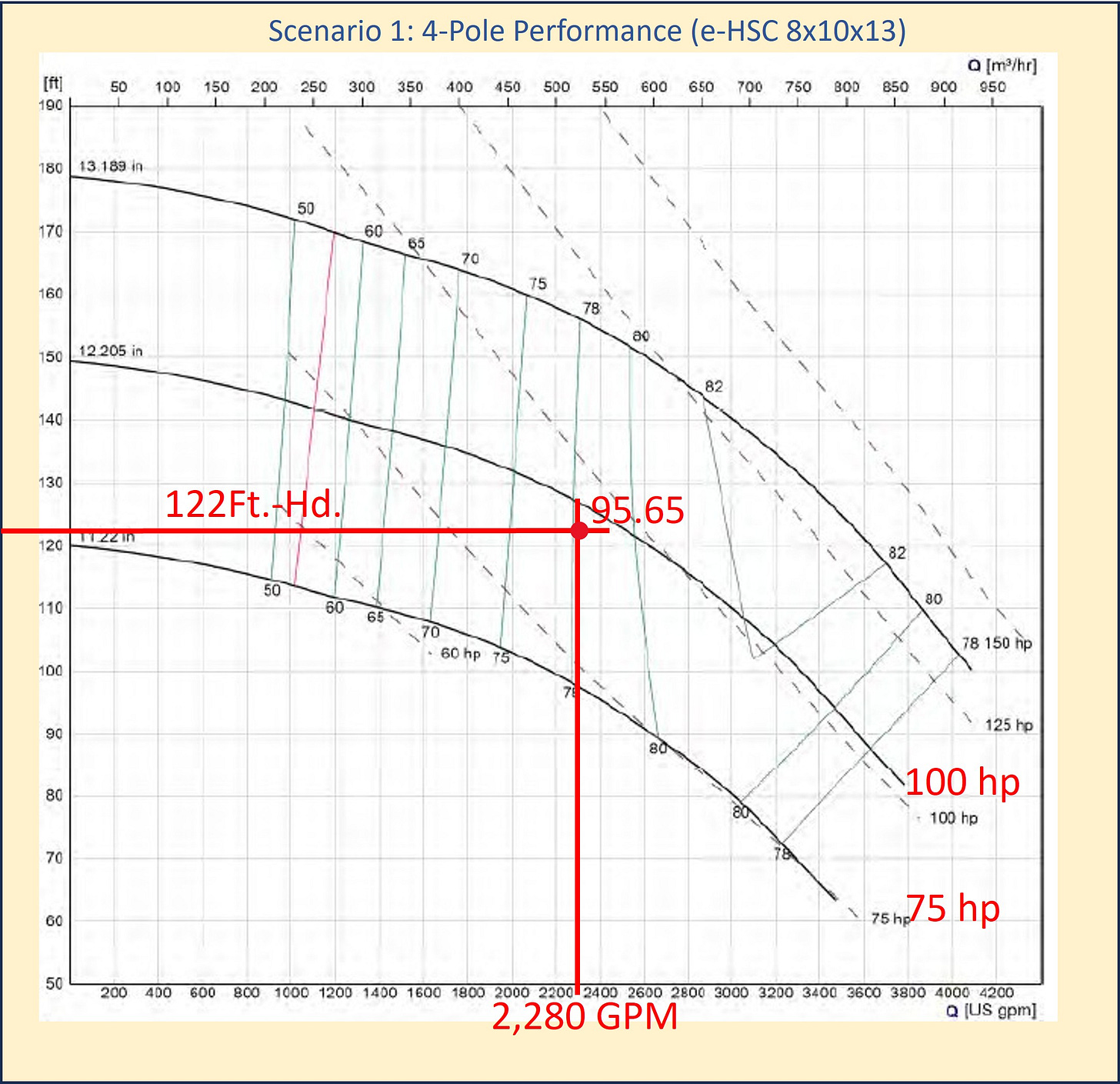

Scenario 1: The original pump selection and Pump curve would plot like this

Scenario 1 the original Design criteria for pure water:

Design tonnage: 950

Design Flow: 2280 G.P.M.

Design system ∆Ft.-Hd.: 122 Ft.-Hd.

Pump B.H.P. 95.6: 100 M.H.P.

Impeller: (12.205”) trim size to 11.91”

Many times the impeller is not trimmed and the TAB contractor must adjust the discharge valve to produce the proper 2,280 G.P.M. and 122 Ft.-Hd. In this situation if the balancing valve were inadvertently left fully opened the motor may be operating in an overloaded condition and the Leaving Water Temperature will increase to 46°F.

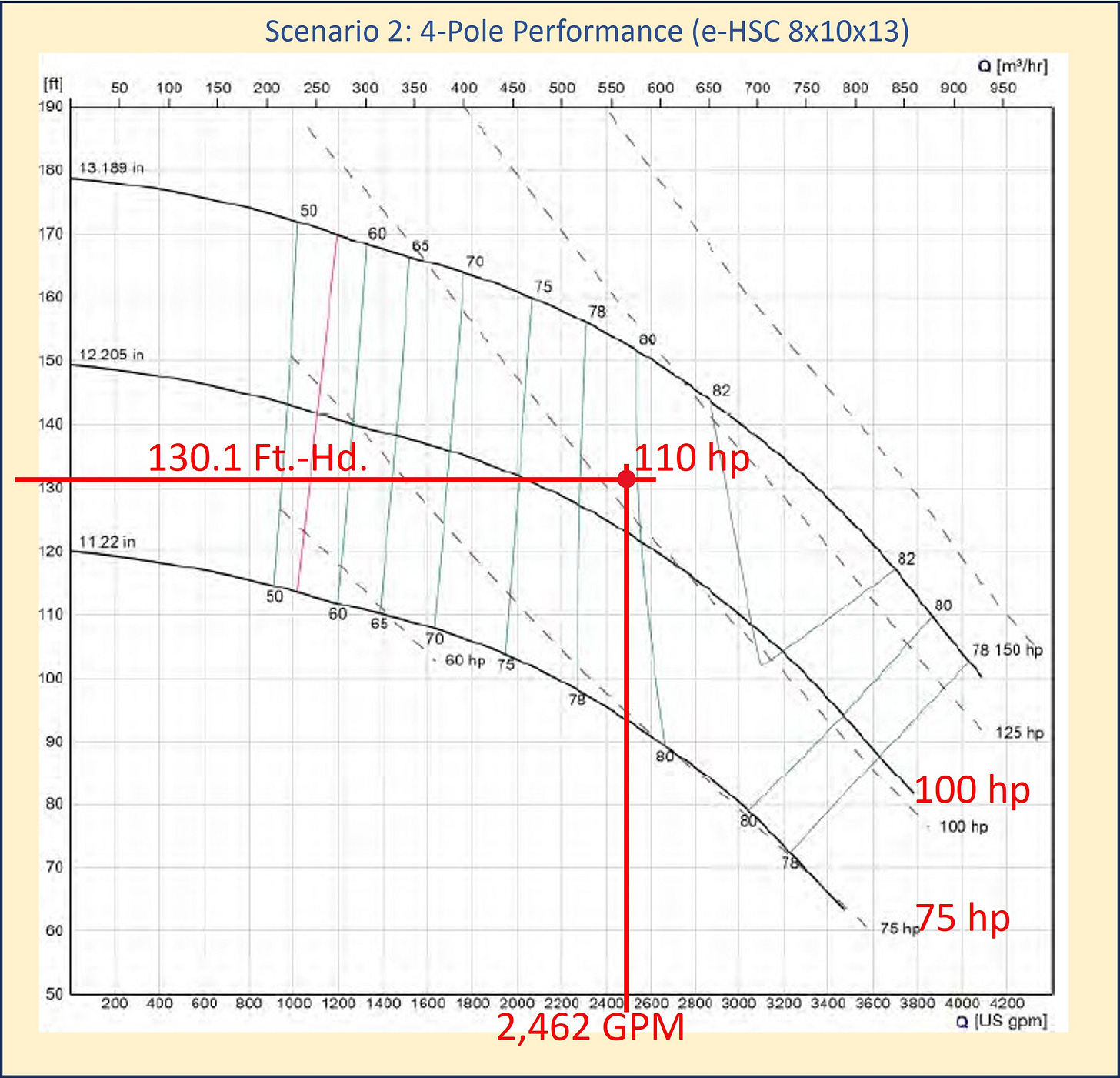

Scenario 2: System plotted based on the numbers we found in the earlier Sessions.

2. Scenario 2 the System Data has been corrected for 45% to achieve design Tonnage

Design tonnage: 950

Corrected Flow: 2,462 G.P.M.

Corrected system ∆Ft.-Hd.: 130.1 Ft.-Hd.

Pump B.H.P. 110; 125 M.H.P.

Impeller: (13.189”) trim size to 12.45”

Notice not only would we require a larger pump motor (125 M.H.P.), but we would also need to increase the impeller size from 12.205” to a 12.45” impeller. That requires a 13.189” impeller to be trimmed down to 12.45” or kept at 13.189” and balanced at the discharge of the pump.

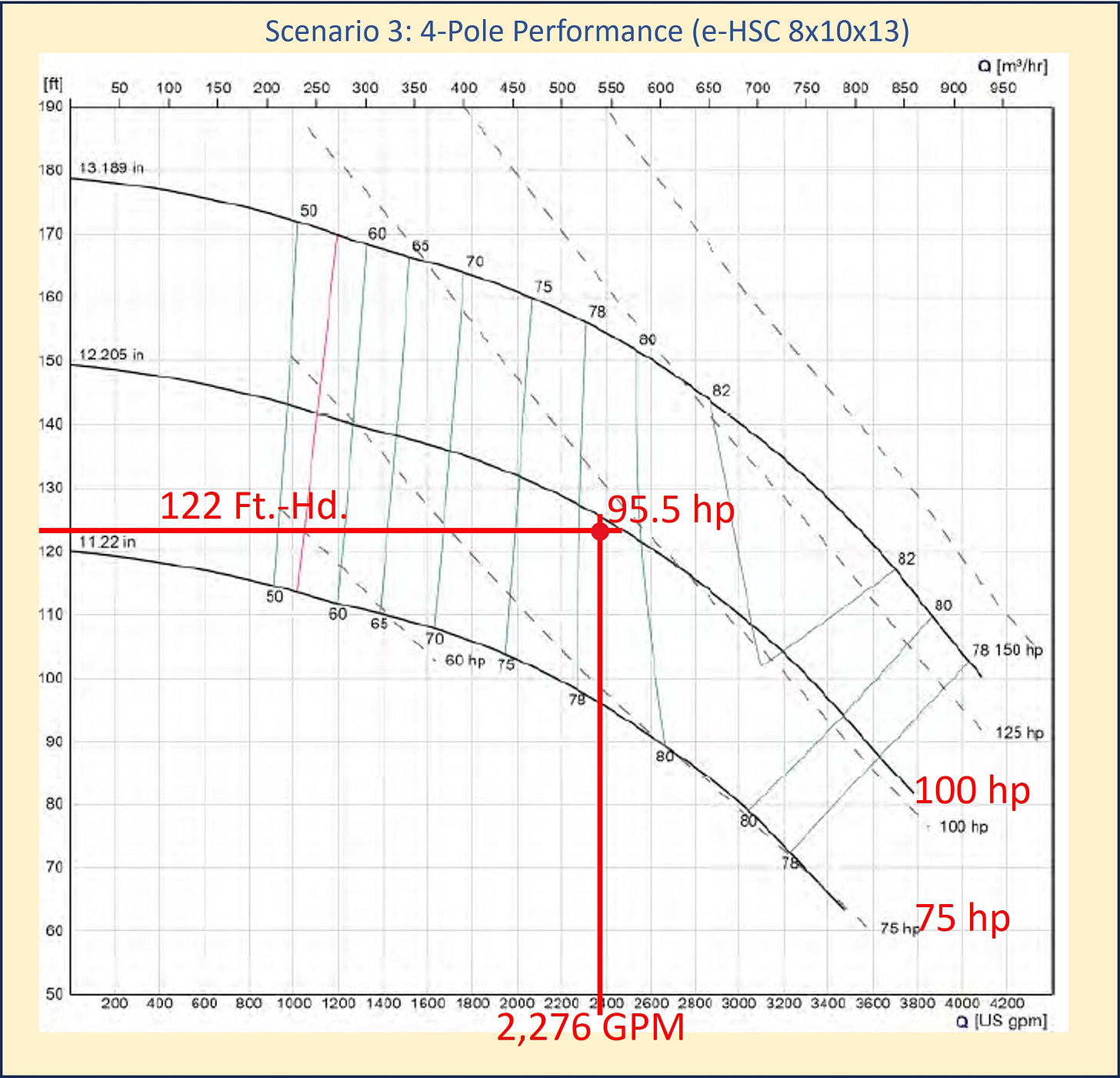

Scenario 3: A best case example when going with a 45% glycol.

3. Scenario 3 the System Data corrected for 45% to achieve listed Tonnage

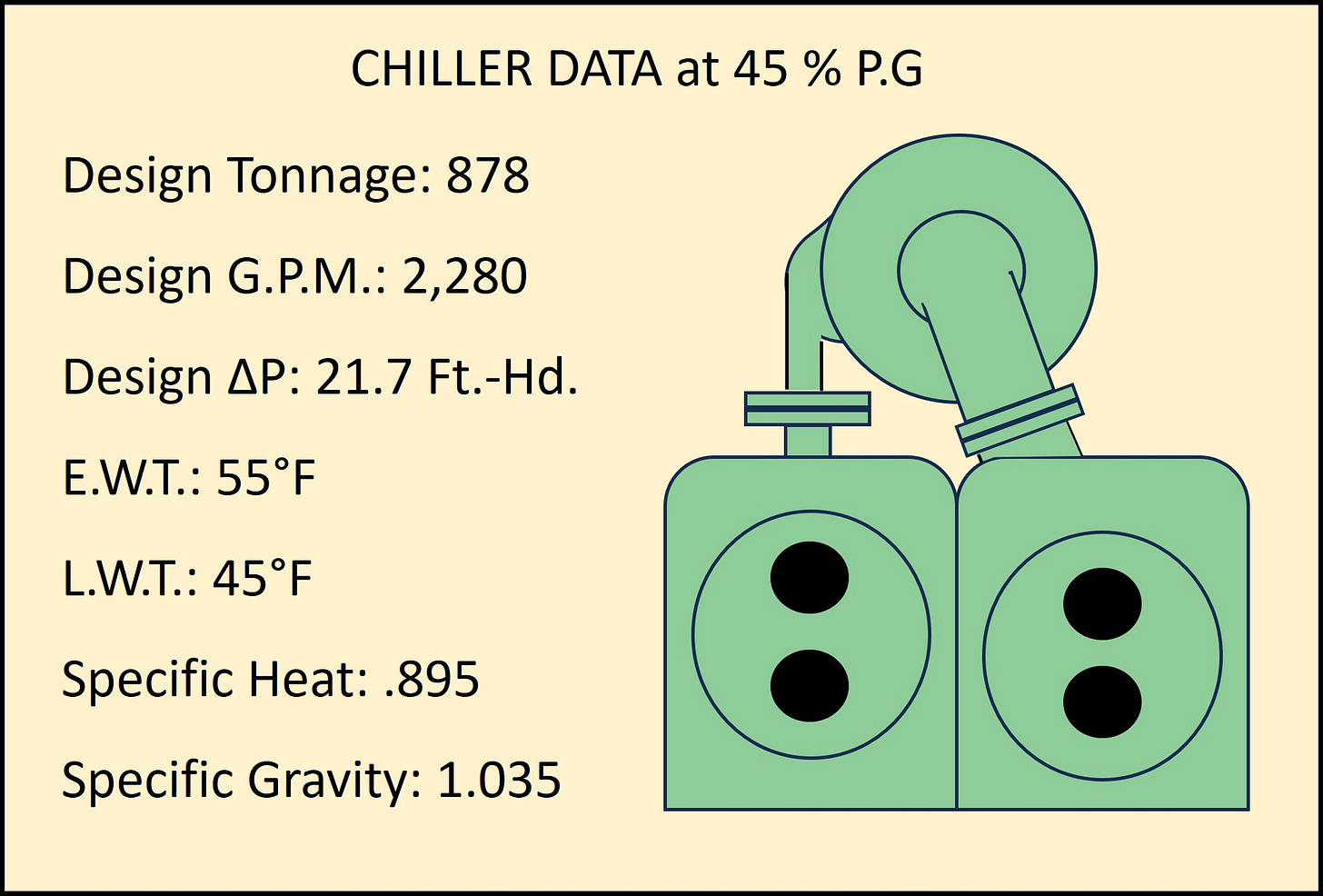

Corrected tonnage: 878

Corrected Flow: 2,276 G.P.M.

Corrected system ∆Ft.-Hd.: 122 Ft.-Hd.

Pump B.H.P. 95.5: 100 M.H.P.

Impeller: (12.205”) trim size to 12.06”

The G.P.M. must be limited to keep the M.H.P. selection below 100. This will only be possible if the original pump impeller size (12.205”) had not been trimmed to 11.91” and the original flow had been achieved by balancing the pump at the discharge.

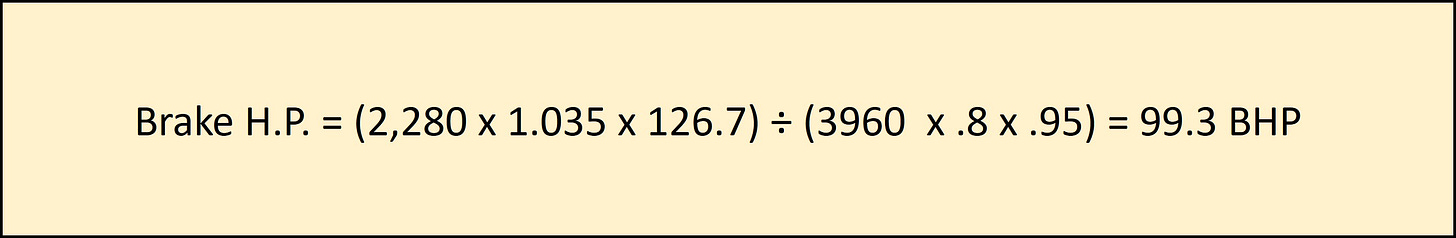

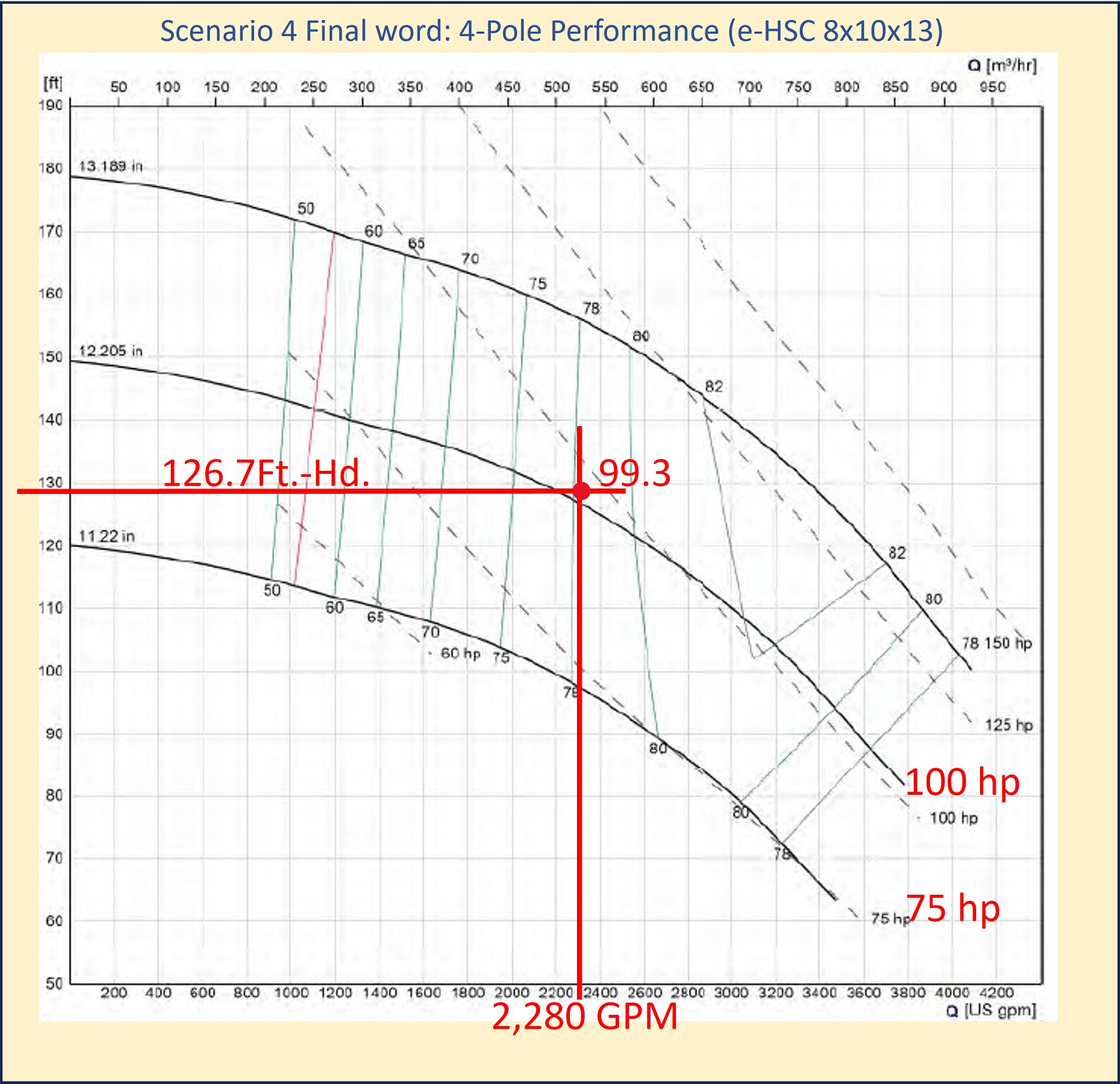

What the final analysis illustrates is that by changing the loop to one with a 45% glycol solution and using the same pump configuration, we loose about 72 Tons or 7.5% of the Chiller’s capacity. If it is not balanced to control the motor Brake Horsepower output we risk exceeding the amperage rating of the motor. Here is a look at the original pump configuration with 2,280 G.P.M. and the adjusted 22.7 ∆Ft.-Hd. for the Chiller and 126.7 ∆Ft.-Hd. total for the system using 45% Glycol. You can see how close we are on M.H.P., it is in risk of exceeding the M.H.P. rating of the motor or at the very least running the amperage into the service factor rating.

The Final Scenario 4:

THE FINAL WORD FOR THE DAY

So, do I expect a mechanic to run this level of analysis to determine if the addition of glycol will cause an issue? No, probably not, but I did want to make you aware that the chiller’s capacity will definitely be affected (reduced).

I also want you to be cognizant of the issues surrounding the addition of glycol to the system pressure drop and the potential to exceed the M.H.P. of the pump motor, especially if the speed of the pump is increased at the VFD to make up for the Chiller’s loss of capacity as we tried to illustrate in the last couple of Issues.

Next week I would like to look at how to develop a system performance curve for a pump and explore Parallel and Series pumping and those applications. We can have a brief discussion about N.P.S.H. and maybe even get into Primary-Secondary pumping. I hope you will join me it should be fun.

Until next week be happy and be safe.

If a mechanic is cognizant what adding glycol will do, they're probably better than someone who will just do it no questions asked. Even if they can't quantify the performance implications.

I’m up for the N.P.S.H. discussion 👍